Variable speed motor controls are important for many industrial applications because they can save energy, improve motor performance, and extend equipment life. Variable speed motor controls provide a stable supply of power to motors with different speeds, which is essential for the operation of certain machinery. In this blog post, I’ll be discussing how these devices work and what you need to know about them before purchasing one.

What is a variable speed motor control, and what are its benefits for motor protection systems?

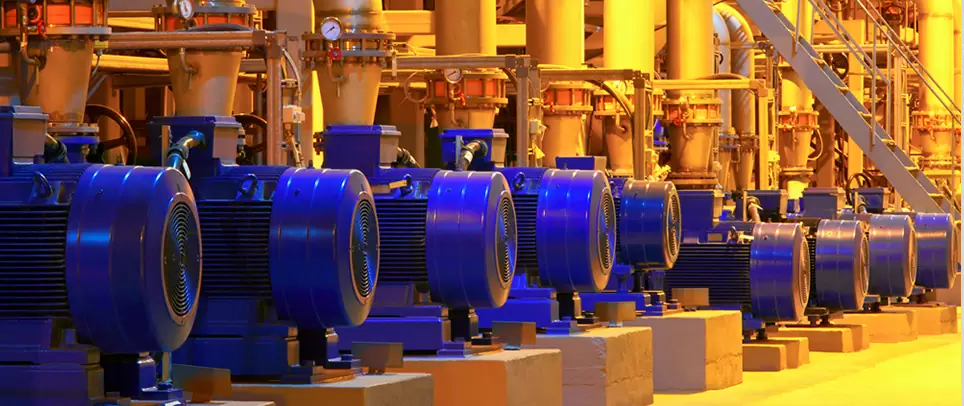

Variable-speed motor control is a device that can be used to control the speed of an electric motor. Variable speed motor controls can be used in a variety of applications, such as controlling the speed of motors that are used in machines, vehicles and other equipment.

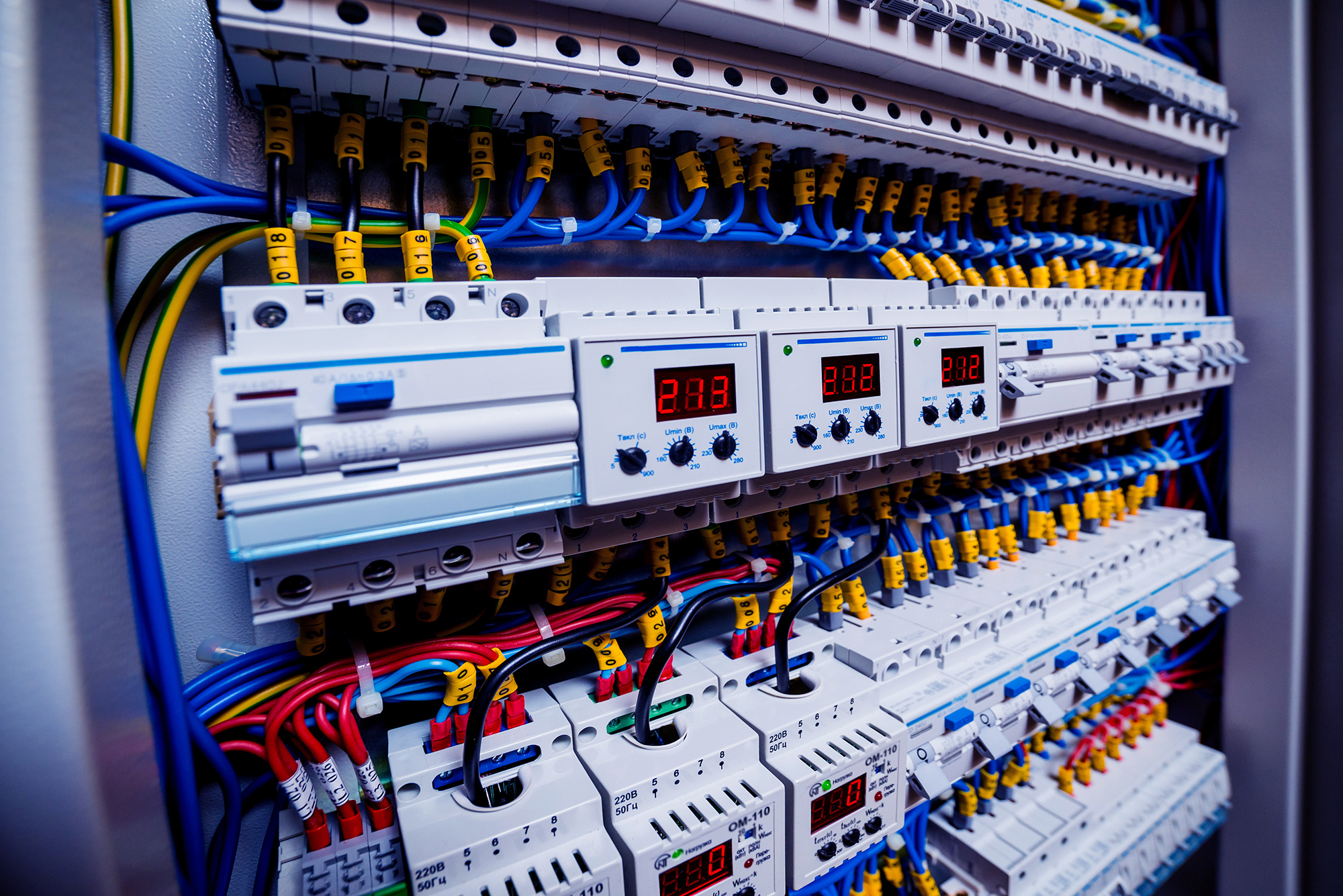

Variable speed motor controls are also known as variable frequency drives (VFD) or adjustable frequency drives (AFD). They work by using an algorithm to monitor a machine’s load and adjust its output accordingly by changing the frequency of its output signal. This means that when there is less load on your machinery, it will slow down, so you don’t have to use as much energy through your machinery.

The different types of variable speed motor controls and how they can be used for specific applications

Variable-speed motor control is a type of motor control that allows you to change the speed of a motor. It can be used for many applications where the speed of the motor needs to be changed dynamically. Some examples include:

- HVAC (heating, ventilation and air conditioning) systems

- Fans and pump motors in refrigeration equipment

- Vacuum pumps

Each type of controller has its own advantages and disadvantages, so it’s important to select the one that best suits the application. For example, AC voltage controllers are less expensive than DC voltage controllers, but they are also less efficient. DC voltage controllers are more expensive but can handle larger loads. Frequency inverters are the most expensive but offer the best efficiency and performance. When selecting a variable speed motor control, it’s important to consider the specific needs of the application in order to choose the best option.

How does a variable speed motor control work to protect motors from damage?

Vsds Electrical is a device used to protect motors from damage. It can be used for controlling the speed of a motor and protecting it from overloading, overheating, short circuits and more. The variable speed controller works by controlling the voltage in phases and running them at different speeds according to needs. This means that if one phase needs to run slower than another, its voltage will be reduced accordingly. This ensures optimum protection for your equipment while still allowing you some flexibility regarding operating speeds.

Conclusion

As we have discussed, variable-speed motor control is a valuable tool for optimizing the operation of your motors and ensuring that they are protected from damage. This technology helps prevent overheating by monitoring the power consumption of individual motors in real-time, allowing you to make adjustments as necessary. It can also be used to adjust torque and frequency so that your motors run more efficiently. For those who are interested in learning more about this exciting new field, check out other posts on our blog!