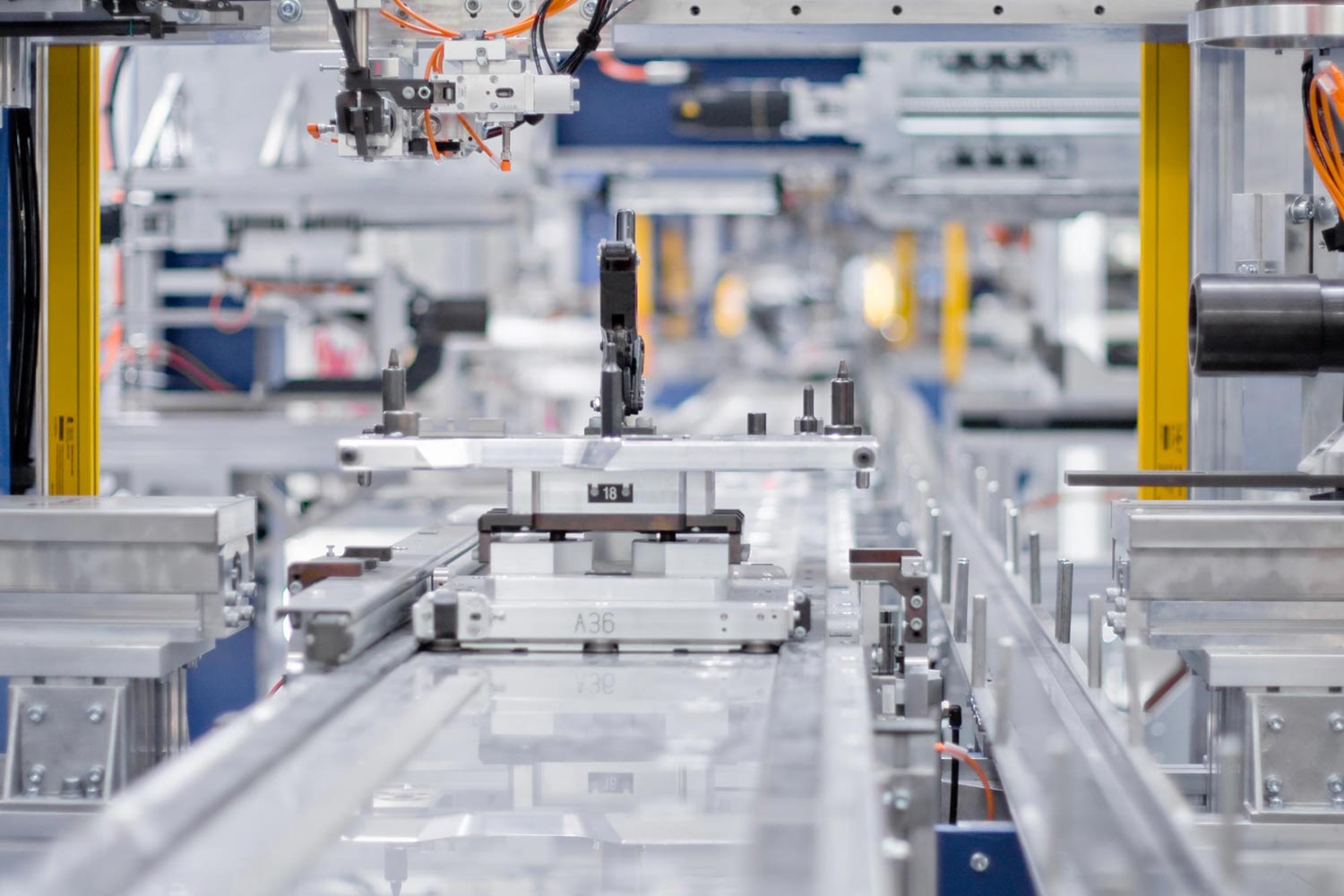

The manufacturing industry is one of the largest and most important sectors in the world. The manufacturing sector is also changing rapidly with Manufacturing Automation emerging every day which can make production more efficient, ensure safety standards are met, and improve quality control across multiple industries. One such technology that stands out among others as an important innovation in this field is automation.

Lower operating costs.

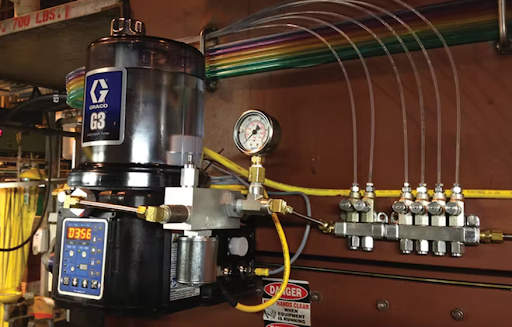

Operating costs are another major cost of manufacturing that can be reduced with automation. The price of the equipment is just one part of this equation; operating costs also include maintenance and labor. Operational savings can come from:

- Reduced material handling costs

- Reduced machine repair and maintenance expenses (because machines don’t make human errors)

- Fewer workers needed to operate the factory floor

Improved worker safety.

Improving worker safety is one of the most significant benefits of manufacturing automation. There are a variety of ways that automated production can help:

- Reduced risk of injury. Manufacturing Automation can make it easier to prevent accidents and injuries, which tend to increase as more human workers are added to a production line. Injuries from repetitive strain injuries are also less likely with robotic processes because robots don’t tire as easily or get frustrated by long hours on the job.

- The reduced risk of workplace accidents and occupational diseases caused by labor-intensive or dangerous work conditions is also reduced when you use robotic machines instead of humans in your manufacturing process.

Reduced factory lead times.

Reducing the time it takes to produce a product is an essential component of any manufacturing process, but it’s often difficult for companies to reduce lead times on their own. However, by automating the production process and reducing human error, manufacturers are able to cut down on lead times significantly.

Automated machinery has the ability to run faster than humans can, so this technology allows manufacturers to produce more products in less time. Additionally, automated machines can be configured with safety features that prevent injuries from occurring during operation — which means that fewer people need to be employed in the factory so that more time can be spent on other tasks.

Increased production output.

Increasing production output is one of the biggest benefits of manufacturing automation. A good quality system will allow you to create a better product and get it out to your customers faster.

A good quality system is essential in any manufacturing process, but especially so when moving into automation. Manufacturing Automation gives us the ability to produce more goods with less effort, but if we don’t have a good quality system in place, then all we have is a large pile of broken or faulty products that no one wants!

Conclusion

As you can see, there are many benefits to implementing a manufacturing automation system. It can help your business meet its production goals, reduce costs and improve worker safety. Manufacturing Automation also allows for more efficient materials handling, which means less waste and less time spent transporting goods from one location to another. If your company is looking for ways to streamline its manufacturing process or increase output, consider investing in an automated system today!